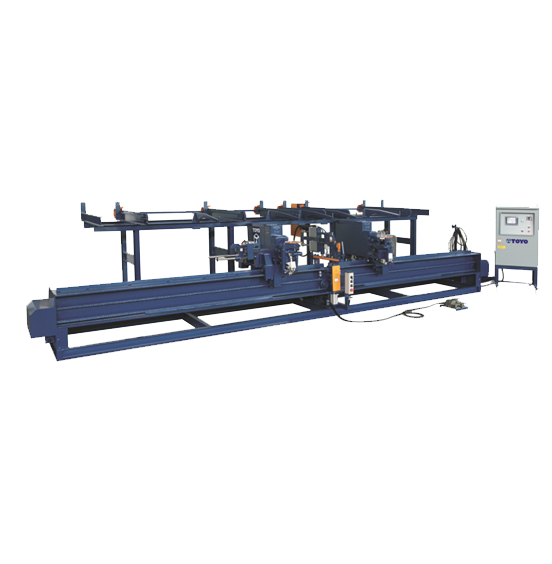

Rebar Threading machine

Network Profile

Topall is a leading supplier of Rebar Threading Machine in India, offering high-performance machines for fast, precise rebar threading on construction sites. Designed for strength and efficiency, our machines help eliminate welding and reduce steel wastage. Join Topall’s growing dealer and contractor network for reliable, site-tested solutions in rebar processing and mechanical splicing.

Rebar Threading Machine – For Stronger, Weld-Free Steel Connections

If you're looking for a fast and safe way to join rebars without welding, the Rebar Threading Machine from Topall is the perfect choice. This machine helps you create strong threads on TMT bars, which can then be joined using couplers. The result Stronger joints, less steel wastage, and no need for lap splicing or on-site welding.

Topall offers reliable, easy-to-use machines ideal for large construction projects where time and accuracy matter.

Why Choose a Rebar Threading Machine?

Topall’s Rebar Threading Machine is designed to work perfectly in real Indian job site conditions—dust, heat, long working hours, and non-stop performance.

Key Features

-

Automatic threading system for fast and clean threading

-

Strong base frame to reduce vibrations during operation

-

Compatible with 16 mm to 40 mm TMT bars

-

Water-cooling system to prevent overheating and increase tool life

-

High-precision rollers that deliver ISO-standard threads

These features ensure every thread you cut is accurate, consistent, and ready for coupler installation.

Where the Rebar Threading Machine Is Most Useful ?

You’ll find this machine useful in a wide range of construction jobs:

-

High-rise buildings – For column-to-column rebar joints

-

Bridges and flyovers – Saves time in rebar assembly

-

Metro projects and tunnels – Avoids space-consuming lap joints

-

Precast factories – Delivers clean threaded bars for fast coupler use

Benefits of Using a Rebar Threading Machine

1. Saves Steel

Since it replaces lap splicing, you save up to 30–40 cm of steel per bar.

2. Speeds Up Construction

A skilled operator can thread 50–60 bars per hour.

3. Safer Than Welding

No fire, no fumes—just a cold mechanical process.

4. Stronger Joints

Threaded bars joined with couplers give full tensile strength.

5. Easy Operation

User-friendly design means faster learning and fewer errors.

Summary

Topall’s Rebar Threading Machine helps you reduce steel consumption, save time, and build stronger joints. With easy operation, high precision, and solid support, it’s the perfect machine for modern construction needs. No more welding hassles—just clean threads and firm connections.

FAQs – Rebar Threading Machine

Q1. What is a Rebar Threading Machine used for?

It is used to create threads at the ends of rebars so they can be joined using couplers instead of welding.

Q2. What bar sizes can it handle?

Topall’s machine handles 16 mm to 40 mm TMT bars.

Q3. How long does it take to thread one bar?

On average, it takes about 25–30 seconds to thread one bar.

Q4. Does it require special power?

Yes, it works on a standard 3-phase power supply.

Q5. Is it easy to maintain?

Yes, regular cleaning and checking the coolant system is enough for long-term use.

Q6. Do you provide on-site training?

Yes, Topall offers installation support and operator training to ensure safe and efficient use.