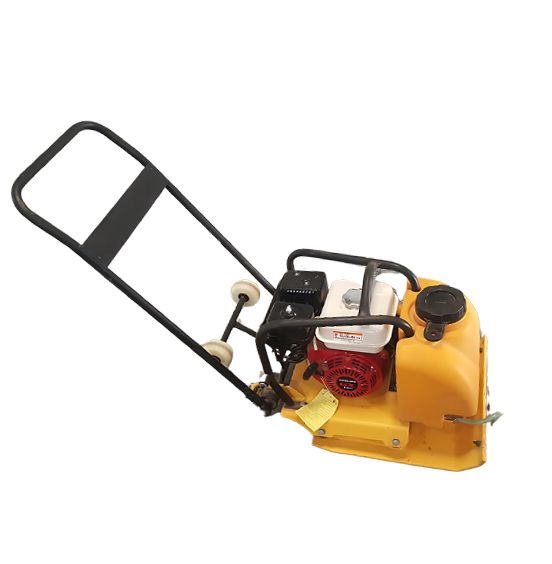

Floor grinding machine

Network Profile

Topall offers high-efficiency floor grinding machines designed for smooth, dust-free concrete surface preparation. Ideal for warehouses, showrooms, basements, and renovation sites, our machines are built for performance and durability. Join Topall’s expanding network to deliver professional concrete finishing with precision and speed across India using our easy-to-operate floor grinding solutions.

Floor Grinding Machine – Turn Rough Concrete into a Smooth, Shiny Floor

A floor grinding machine is the quickest way to transform uneven, stained, or rough concrete into a clean, level, and polished surface. Instead of tearing out an old slab, you can grind away high spots, open the pores, and even polish to a mirror shine—all with one efficient tool.

At Topall, we build compact, easy to use grinders that help contractors finish floors faster, with less mess and lower cost.

What a Floor Grinding Machine Does?

The floor grinding machine uses rotating diamond segments to shave off a thin layer of concrete. In one sweep it removes coatings, smooths bumps, and prepares the slab for coatings, tiles, or stains. With finer grits, you can keep grinding until the surface takes on a glossy finish that’s both tough and attractive.

Key Features of floor Grinding Machine

1. Variable speed motor

Choose low rpm for coating removal or high rpm for polishing, all from a single dial.

2. Integrated dust hood

Connect a vacuum and keep the air clear—no clouds of concrete dust on site.

3. Quick change diamond plates

Swap grits in seconds; no special tools needed, so downtime stays minimal.

4. Fold down handle

The grinder fits in small elevators and pickups, making transport simple.

5. LED work light

Brightens the work path so you never miss a scratch or low spot.

Where the Floor Grinding Machine Works Best ?

-

Warehouse floors needing a dust free, durable surface

-

Showrooms that demand a high gloss finish to impress customers

-

Parking basements where smooth drainage slopes are essential

-

Old factory floors being prepped for epoxy coatings

-

Residential slabs ready for decorative staining

Benefits of Using a Floor Grinding Machine

-

Saves time – One operator can cover up to 250 m² in a single shift.

-

Improves adhesion – Opens concrete pores for better bonding of sealers or epoxy.

-

Reduces dust – Built in vacuum port keeps the site cleaner and safer.

-

Cuts costs – Refurbish existing slabs instead of replacing them.

-

Boosts curb appeal – Polished concrete reflects light and stays easy to clean.

How to Use the Machine – Simple Steps

-

Inspect the slab and mark cracks or high spots.

-

Fit coarse diamonds to remove coatings and level the floor.

-

Vacuum debris, then switch to medium grit for smoothing.

-

Finish with fine grit or resin pads for a glossy polish.

-

Apply sealer to lock in the shine and protect against stains.

Summary

A floor grinding machine turns rough, tired concrete into a smooth, long lasting surface in a fraction of the time manual methods take. With Topall’s robust build, variable speed, and dust free design, you get professional results on every job—whether you’re prepping for epoxy, polishing for a showroom, or simply flattening a warehouse slab.

FAQs – Floor Grinding Machine

Q1. How long does it take to grind a 100m² floor?

About half a day with a single floor grinding machine, depending on the starting condition.

Q2. Can it remove epoxy or paint?

Yes. Start with coarse diamonds and the grinder will strip most coatings in one pass.

Q3. Does grinding weaken the concrete?

No. It removes only a thin surface layer and can actually increase surface density when polished.

Q4. What power supply is required?

Most models run on 415V three phase, but smaller 220 V single phase units are available.

Q5. How often do I change diamond segments?

Segment life depends on grit and floor hardness, but a set typically lasts 300–500m².

Q6. Is a vacuum mandatory?

Using a vacuum is strongly recommended. It keeps the air clean and extends diamond life by removing grit.