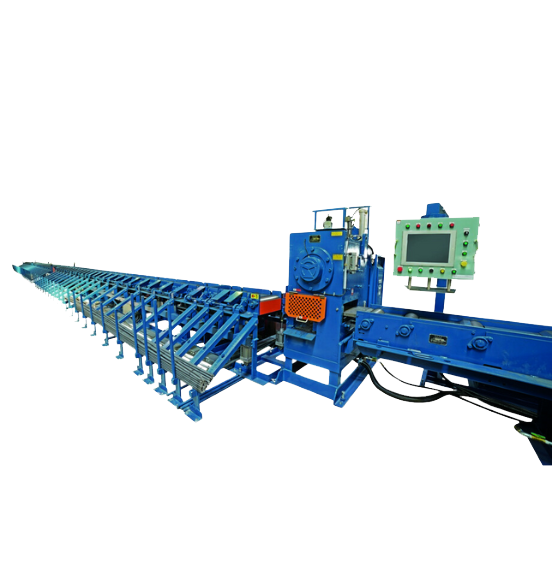

Automatic Bender Line

Network Profile

Topall delivers high-speed and reliable Automatic Bender Line machines for precision bending of TMT bars in construction and rebar processing sites. Designed to save time and labour, our machines offer accurate shaping with minimal waste. Join Topall’s expanding dealer and contractor network across India and enhance your steel fabrication with automated bending technology that delivers results.

Automatic Bender Line – Turn Raw Rebar into Ready to Use Shapes in Minutes

Moving bars from loose bundles to bent, project ready shapes is often the slowest step on a jobsite. An automatic bender line changes everything. Feed straight bars at one end, and the system measures, cuts, bends, and stacks stirrups or custom shapes at the other—no manual handling, no lost time.

Why Choose an Automatic Bender Line?

A good automatic bender line lets a small crew do the work of a full steel yard. With touch screen controls and servo motors, it delivers repeatable shapes that fit first time. You save labour, reduce waste, and keep your schedule on track.

Key Features Explained in Two Line Points

1. Servo Measuring Wheel

Keeps length tolerance within ±1 mm, so every piece matches design drawings.

2. Dual Direction Bending Head

Rotates both clockwise and counter clockwise, forming complex bends without flipping the bar.

3. Automatic Stacker

Finished pieces slide onto a collecting rack, ready for tying or transport—no lifting by hand.

4. Shape Memory Library

Stores hundreds of common designs; select, adjust size, and press start.

5. Safety Light Curtains

Stop the line instantly if anyone reaches inside the guarded zone.

Where an Automatic Bender Line Shines

-

High rise towers that need thousands of identical stirrups every day

-

Bridge and flyover projects where exact bends prevent costly rework

-

Precast concrete plants demanding tight tolerances for mould fit

-

Metro rail tunnels with limited space and strict timelines

Step by Step Workflow

-

Feed bars onto the roller table—8 mm to 32 mm diameters.

-

Set shape on the touch screen or pick from saved programs.

-

Machine measures and cuts each bar to length.

-

Bending head forms single or multiple angles in one pass.

-

Stacker collects the finished pieces in neat bundles.

In about 30 seconds, raw bar becomes a ready to tie stirrup.

Benefits in Plain Language

-

Less labour – One operator runs the whole line.

-

Faster output – Up to 1,800 bends per hour.

-

Lower waste – Accurate measuring means no excess off cuts.

-

Better safety – No manual bending reduces strain injuries.

-

Consistent quality – Every bend meets code without guesswork.

Summary

An automatic bender line turns steel processing from a bottleneck into a smooth, predictable flow. It helps contractors cut costs, speed up schedules, and deliver stronger, code compliant structures. With Topall’s solid build and nationwide support, you buy once and benefit on every project.

FAQs – Automatic Bender Line

Q1. What bar sizes does the line handle?

It bends bars from 8 mm to 32 mm without tool changes.

Q2. How many shapes can I store?

The control panel holds hundreds; just name, save, and reuse anytime.

Q3. Does it need three?phase power?

Yes, a 415 V supply keeps the motors and hydraulics running smoothly.

Q4. How fast is production?

A skilled operator can produce up to 1,800 bend cycles per hour.

Q5. Is training required?

Basic training takes one day; the touch screen interface is simple and menu driven.

Q6. What maintenance is involved?

Daily cleaning, weekly lubrication, and a monthly check of blade and roller wear keep the line performing at its best.